Know-How

Printers & Printing technique

This hobby started with a simple printer from FlashForge (Adventurer 3) in 2018.

With growing enthusiasm for this hobby and the increasing application possibilities, we then expanded and purchased - with the first earned money - a more professional IDEX printer, a FlashForge Creator 3Pro in 2020, in order to be able to produce larger components and benefit from the additional capabilities of IDEX printing. IDEX printing enables either the simultaneous printing of 2 identical components in parallel operation, or the printing of one object with two different materials (like water dissolving supports).

In the meantime, we have acquired a taste for it and have replaced these first printers which are rather for the private hobby sector, with professional printers from Bambulabs (filament printers) and FormLabs (liquid resin printers).

Equipment

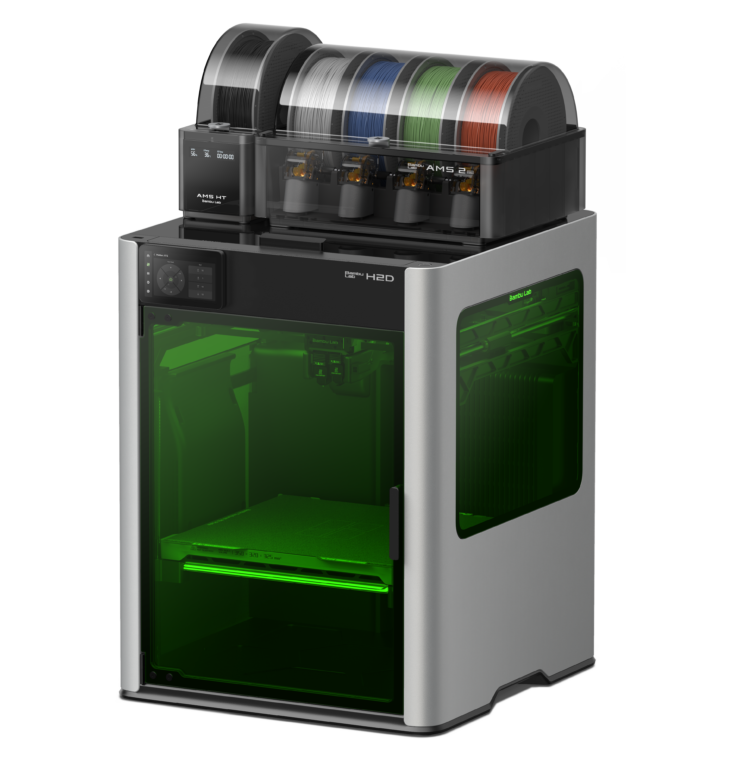

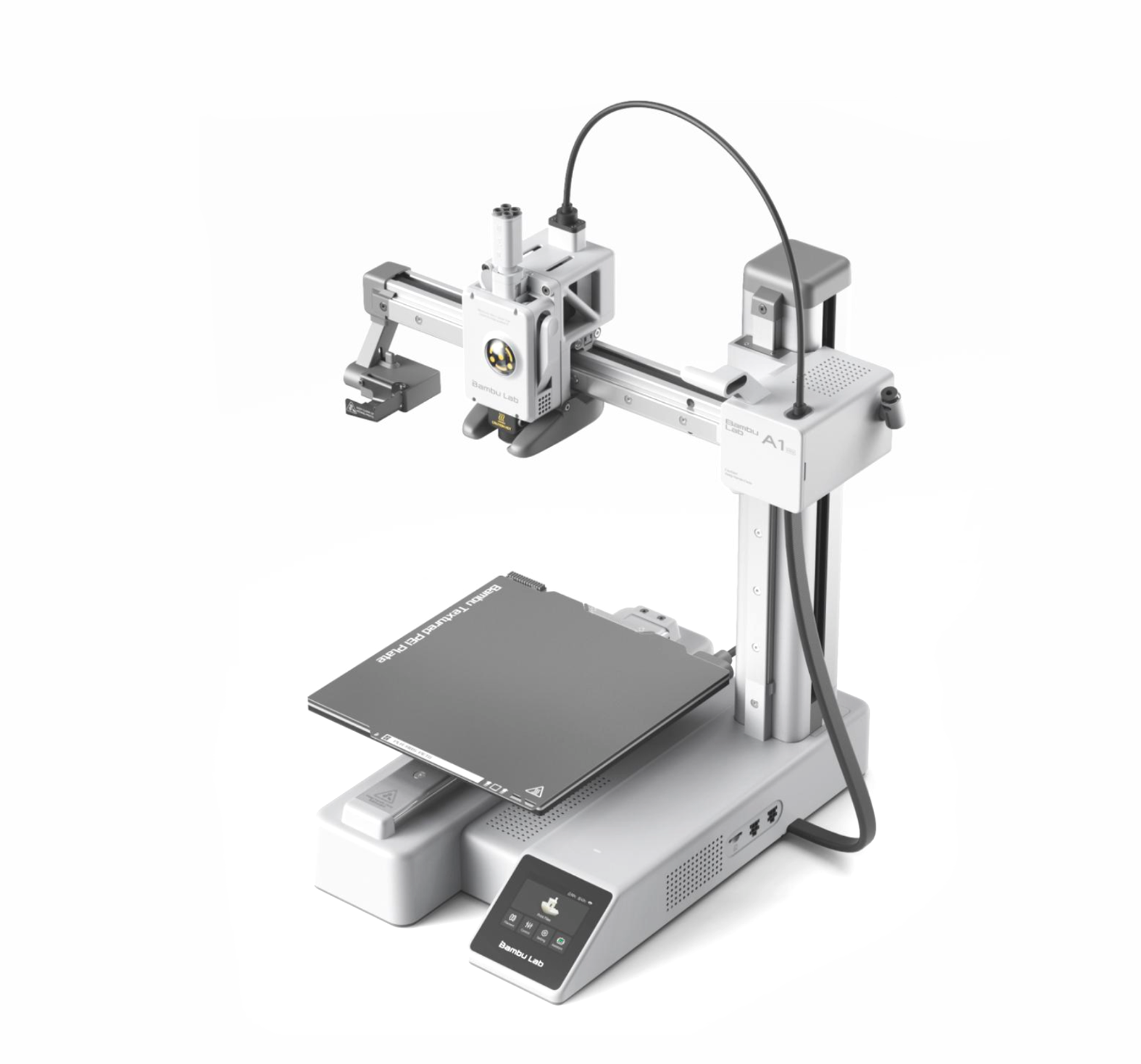

As of July 2025 we've added a BambuLabs H2D Combo Dual Nozzle with 10W laser with 4x AMS to our setup, joining the an X1Carbon with 4x AMS and an A1 Mini, serving the filament printing segment. This enables components up to a dimension of 35.0cm x 35.0cm x 35.0cm and an accuracy of 0.2mm.

In the filament printing process, a plastic cord with a thickness of 1.75mm is melted in a nozzle at material-specific temperatures between 190-360°C and printed in >0.1mm layers, layer upon layer. We print with PLA, PETG, PCTG, ABS, ABS-GF, ABS-CF, ASA, TPU, PETG-CF, PETG-CF and many other materials.

H2D Combo 10W Laser & 4xAMS:

350 × 320 × 325mm³

X1C Combo & 4x AMS:

256 × 256 × 256 mm³

A1 Mini

180 x 180 x 180 mm³

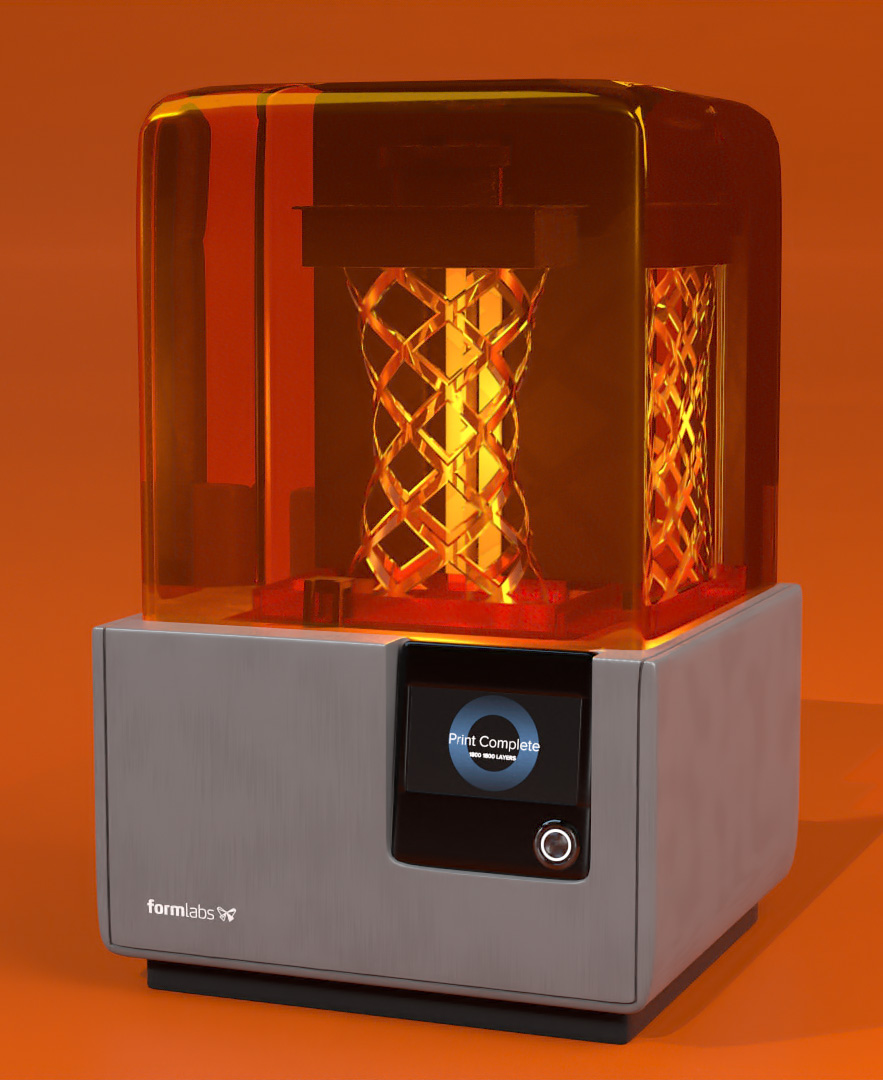

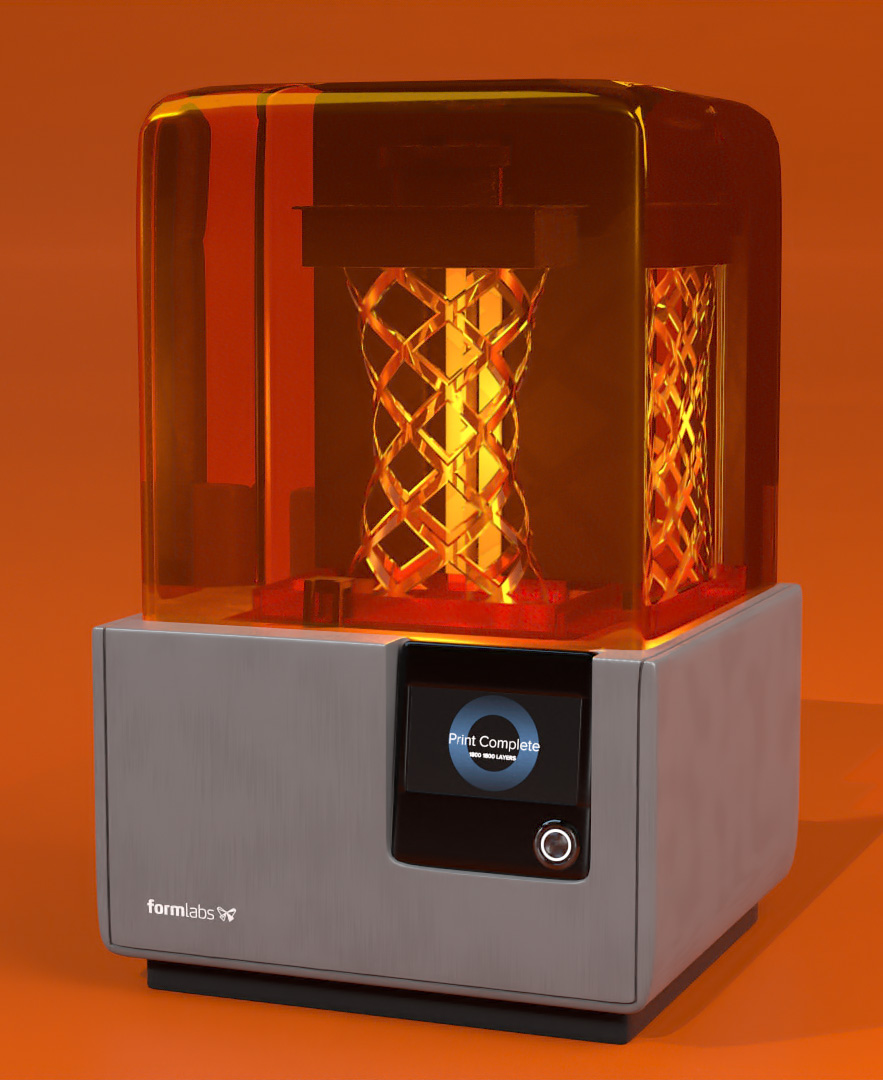

But sometimes it has to be even more precise and detailed, which is why a resin/resin laser printer from FormLabs has found its way into our business.

FormlabForm2

FormlabForm2

The FormLabs Form 2 Laser Resin printer can print parts up to a dimension of 14.5cm × 14.5cm × 17.5cm and an impressive accuracy/layer thickness of 0.025mm (which translates into 40layers per mm).

This printer is mainly used in the dental industry to print biocompatible dentures and denture crowns.

Resin printing is considerably more time-consuming and labor-intensive and consists of three work steps.

A liquid UV-sensitive synthetic resin is used, which is exposed in wafer-thin layers using a violet class 1 laser (405 nm, 250 MW) (see video).

*Video in real time

In the first step, a plunger is immersed into the with resin filled resin tank until only a thin layer of resin, with a thickness of 1/40 mm (25 nm) remains, which is then selectively exposed by the laser beam and thus cured. The resin tank shifts, the plunger rises, resin flows back into the plunger area. The plunger lowers and displaces the resin again, so that the next layer can be "shot". The print thus slowly grows upside down out of the liquid resin.

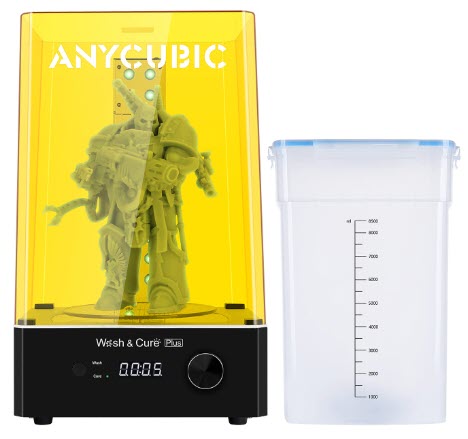

In the second step, the print must be carefully detached from its support structures using gloves and safety goggles, without direct exposure to light and freed from excess liquid resin in a washing process in a 99% pure alcohol bath. After carefully dabbing off the remaining alcohol and briefly drying in the air, the print is then fully cured in a UV curing chamber in the final step.

Anycubic Wash Cure

This printer is used for the production of:

This printer is used for the production of:

- technical components with requirements for maximum accuracy

- denture crowns

- Components that require a temperature resistance of over 100°C

- Jewelry production (with subsequent electroplating and metal finishing)

- Printing of figurines for role-playing games etc.

Further services we offer:

Electroplating of components (on request)