Gear for electrical step (like of Project2000/Reimo)

Stainless steel gear rod as spare part for steps of the Reimo Project2000 step and other models (type 10856 steps).

With this article, we were often much closer to despair than a solution.

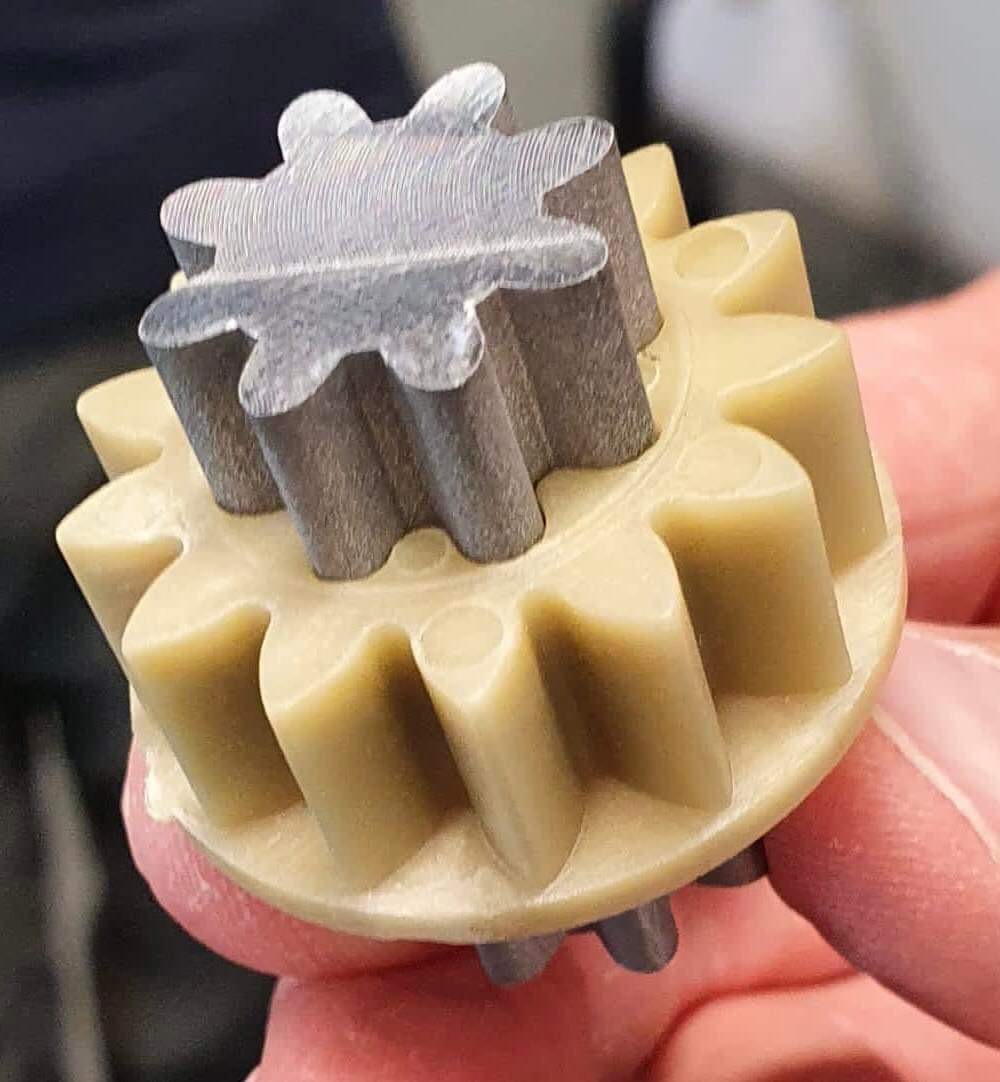

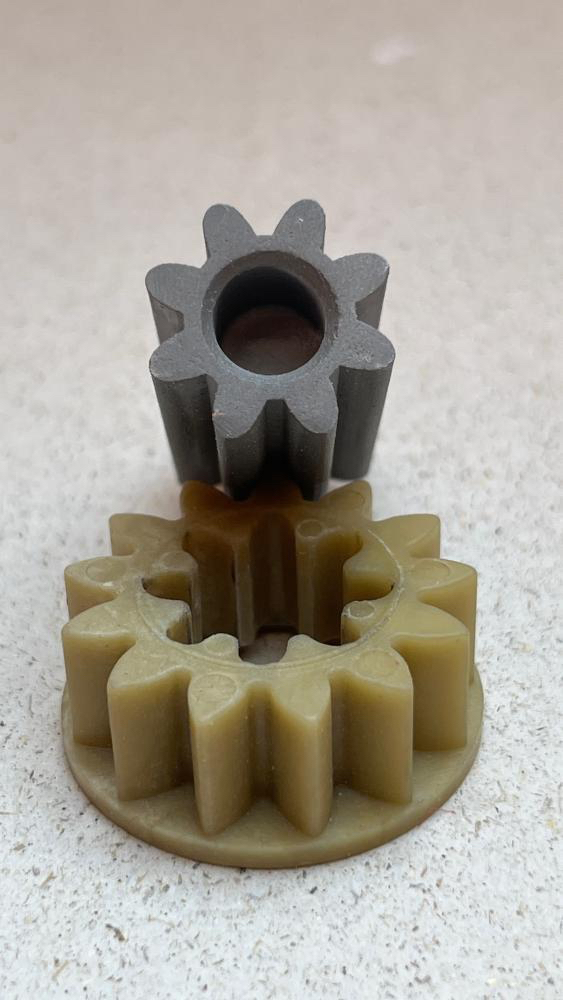

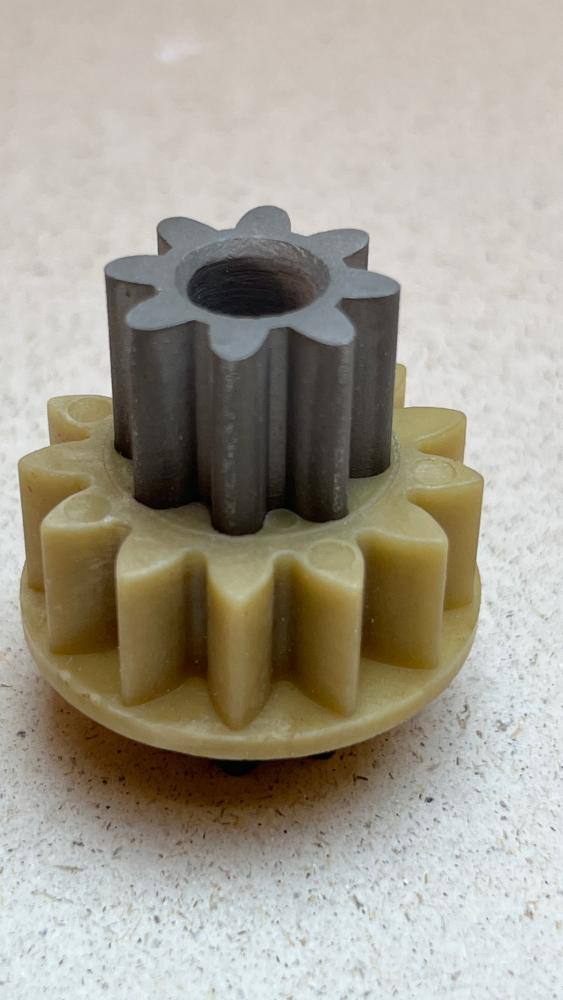

The original nylon gear rod of the Reimo Project 2000 step series, as well as all models of step type 10856, are equipped with a gear rod. This rod is inserted directly into the motor drive on one side and held on the opposite side with a pin. The actual drive pinion comes around this gear rod and can slide up and down on the gear rod. This drive pinion drives a twin pinion and one of the two large drive wheels for the step extension.

This gear rod is subject to high shear forces. Design errors and some points that must be observed during installation will sooner or later lead to breaking/tearing of the rod as it cannot withstand the shear forces.

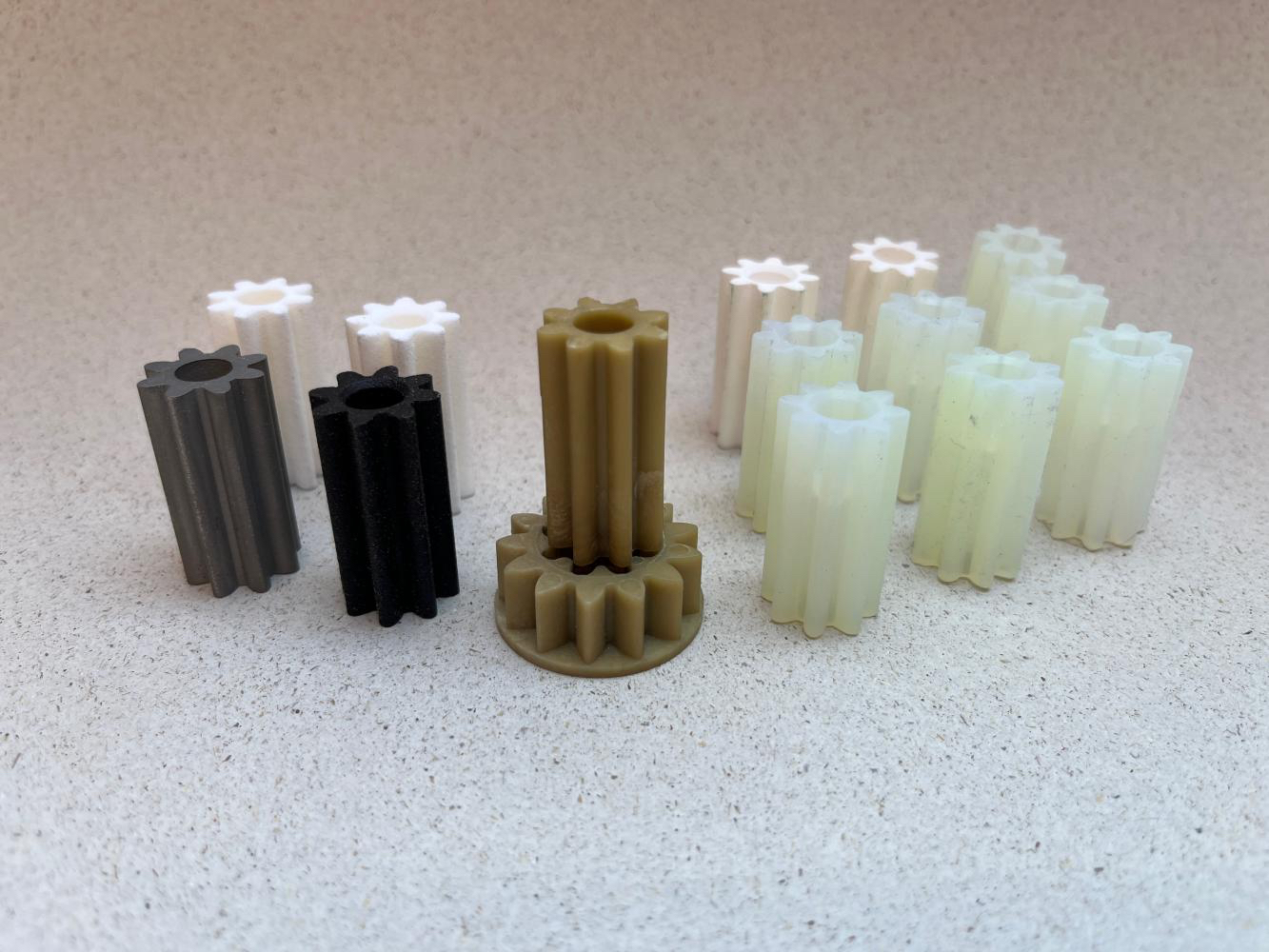

After we had been able to reproduce this gear rod in the CAD tool, which in the original comes with astonishing fitting inaccuracies, unequal geometries for each individual tooth of the gearwheel and other inaccuracies, we tried in countless attempts and from countless materials to get a model printed that is at least equivalent to the original part.

The filaments used included ABS, PETG, PCTG, carbon fiber and glass fiber-reinforced materials, etc. - and all of them burst when subjected to shear forces during the breakage test. In total, we created and destroyed 37 prototypes.

We also used a variety of resin materials. Some of them were ordered from other users so that we didn't have to buy every resin ourselves (€150 - €750 per liter).

The “Durable” resin from FormLabs, which is specially designed for gear wheels, was very promising.

We produced 20 of these gear rods and provided 10 of them to testers free of charge (shipping costs only). In the course of time, however, 7 of the 10 testers also broke these gear rods within the first 6 months.

In the meantime, parallel to our own tests, we had also requested the production of small series in aluminum via various contacts and channels. However, these could not be realized at an acceptable price (over 45,-€ p.pcs. in the EK with a purchase quantity of 100 pcs.). Brass or copper would also have been perfect materials, but these were even less feasible for cost reasons.

After almost 7 months, we have managed to find a supplier who can produce this gear rod in stainless steel at an acceptable price (close to the original rack) if we order a minimum quantity of 100 pieces and pay in advance.

We received the final prototypes yesterday and identified the model that fits perfectly and over which the drive pinion slides perfectly, just like on the original rod.

Link to mounting instructions.

Now available in our shop in limited amount.

Link to item in shop.